Extreme Conditions

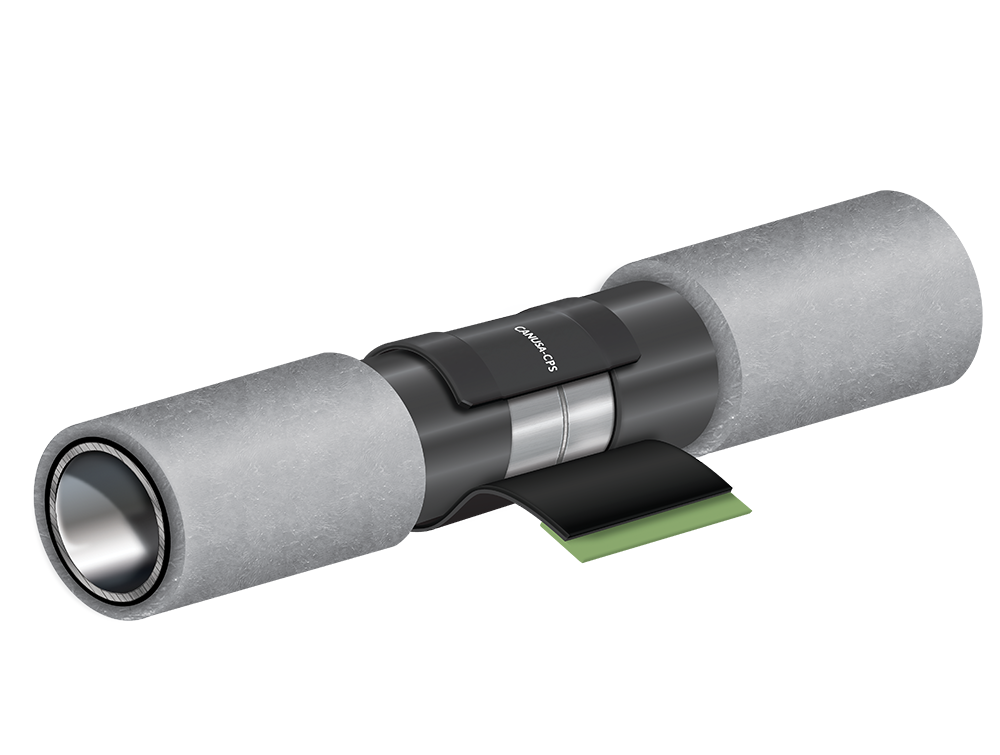

XCS

Protective coating for extreme conditions.

Protects live, flowing pipelines.

Flexible & reliable installation.

No pre-heat.

The XCS system is designed for use in extreme conditions, including cold weather applications and rehabilitation of pipeline coatings.

XCS Extreme Condition System utilizes a crosslinked polyolefin backing, coated with a protective heat activated adhesive which effectively bonds to most substrates and common pipeline coatings. XCS is designed to protect live, flowing pipelines where pre-heating of the substrate is not possible. XCS is also designed for cold weather application, as well as custom application and usage. These sleeves are supplied with a black backing that is stabilized against ultra-violet degradation.

Assured Protection

- XCS is made from materials that provide high electrical resistivity, resistance to corrosive environments, low water absorption, low moisture permeability and an effective bond to both the steel surface and to common pipeline coatings.

- When the sleeve is heated, the adhesive is transformed into an amorphous, low viscosity liquid, which has excellent bonding to the substrates.

Flexible & Reliable Installation

- XCS sleeves are available in widths up to 36” (900mm) and can be applied in overlapping sleeve segments along the pipe length, or as a standard field joint coating.

- XCS is available as one-piece wraparound sleeves or as a bulk roll with a separate closure for greater flexibility.

No Pre-Heat

- XCS sleeves can be used to coat live lines operating between 10°C (50°F) and 50°C (122°F).

- No preheat is necessary for ambient temperature installations.