Corrosion Protection

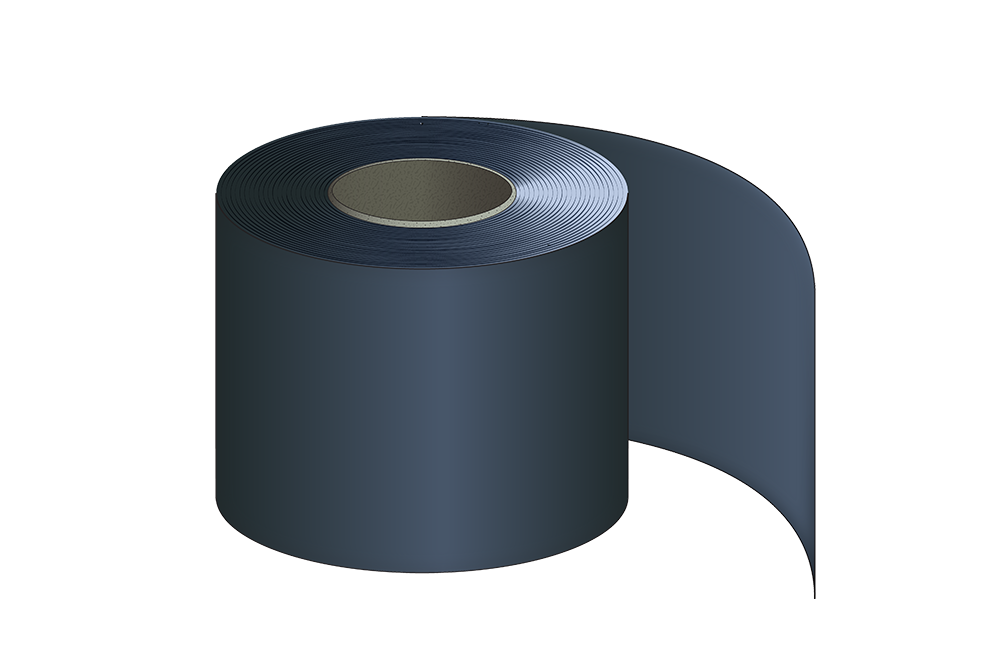

WrapidTape

Protective barrier against corrosion.

Easy installation.

Saves time and money.

Long term protection.

Canusa WrapidTape consists of a crosslinked polyolefin backing, coated with a protective, heat active anti-corrosion adhesive which effectively bonds to steel substrates and common pipeline coatings including polyethylene and fusion bonded epoxy.

The WrapidTape products are designed to Offer superior protection on bends, fittings, reducers and other pipe structures where a typical WrapidShrink™ product cannot be applied.

Easy Installation

- The flexibility provided by the thinner tape dimension allows WrapidTape to effectively protect both conventional substrates such as circular pipe as well as irregular transitions such as elbows and risers. Upon the application of heat, the specially formulated adhesive flows into all surface irregularities, forming a protective barrier against corrosion.

Saves Time & Money

- WrapidTape is quick and easy to install. Since no special priming or operator equipment is required, product installation is quick and labour costs are kept to a minimum. Unlike conventional cold-applied tapes, WrapidTape does not require the use of high volatile primers, further minimizing costs and risks to health and safety.

Long Term Protection

- WrapidTape is manufactured using materials that provide high electrical resistivity, low water absorption and low moisture permeability. The unique crosslinking process results in a protective backing that is much tougher than conventional tapes, more effectively resisting abrasion and damage, and thus extending the lifetime of the substrate. WrapidTape can also be double or triple wrapped for extra mechanical protection when required.