Canusa-CPS is known for sealing and corrosion protection of pipeline joints and other critical infrastructure in the following markets: oil and gas onshore & offshore, district energy, water pipelines, repair and rehabilitation of industrial & civil infrastructure.

High-quality applications in even the toughest environments.

High-quality applications in even the toughest environments.

Since 1966

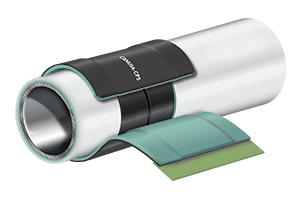

Product Line

Canusa-CPS delivers innovative solutions to increase the integrity of critical infrastructure with an ever-increasing focus on advanced corrosion protection and automated field application equipment to provide reliable, safe and efficient protection of assets over their lifetime.

Canusa-CPS offers

-

50+ years of brand equity, known for integrity, execution and trust

-

Trusted partnerships on the world’s largest and longest pipeline projects

-

Reliability in meeting industry design and construction challenges

-

Safer, easier, field-friendly applications in the toughest environments

-

Unparalleled commitment to equipment, training and field resources for our customers

-

A legacy of innovation and leadership in offshore and onshore markets

-

Extensive offshore experience with leading edge technologies across all sectors of industry

55

Years as Field Joint Coating Solutions Leader

60

Diverse coating products spread across 5 different segments: Heat Shrink Sleeves, Sealants, Liquid Epoxies, Visco-Elastics, Mechanical Protection

1

Globally in Automated Application Solutions for Field Joint Coating Products

55

Years as Field Joint Coating Solutions Leader

60

Diverse coating products spread across 5 different segments: Heat Shrink Sleeves, Sealants, Liquid Epoxies, Visco-Elastics, Mechanical Protection

1

Globally in Automated Application Solutions for Field Joint Coating Products