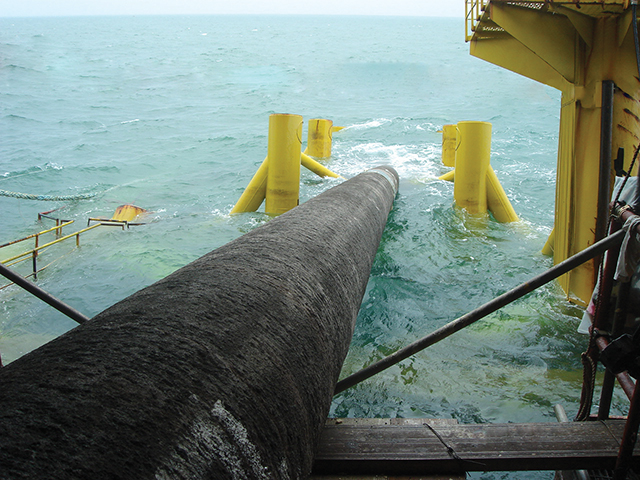

High Build Epoxy Coating for Offshore Corrosion Protection

HBE-OS

Only liquid coating of its kind serving the

offshore marketplace.

Fastest offshore cycle-times.

Environmentally friendly.

Reduced installation times.

The Canusa HBE-OS is the only liquid coating of its kind serving the offshore marketplace.

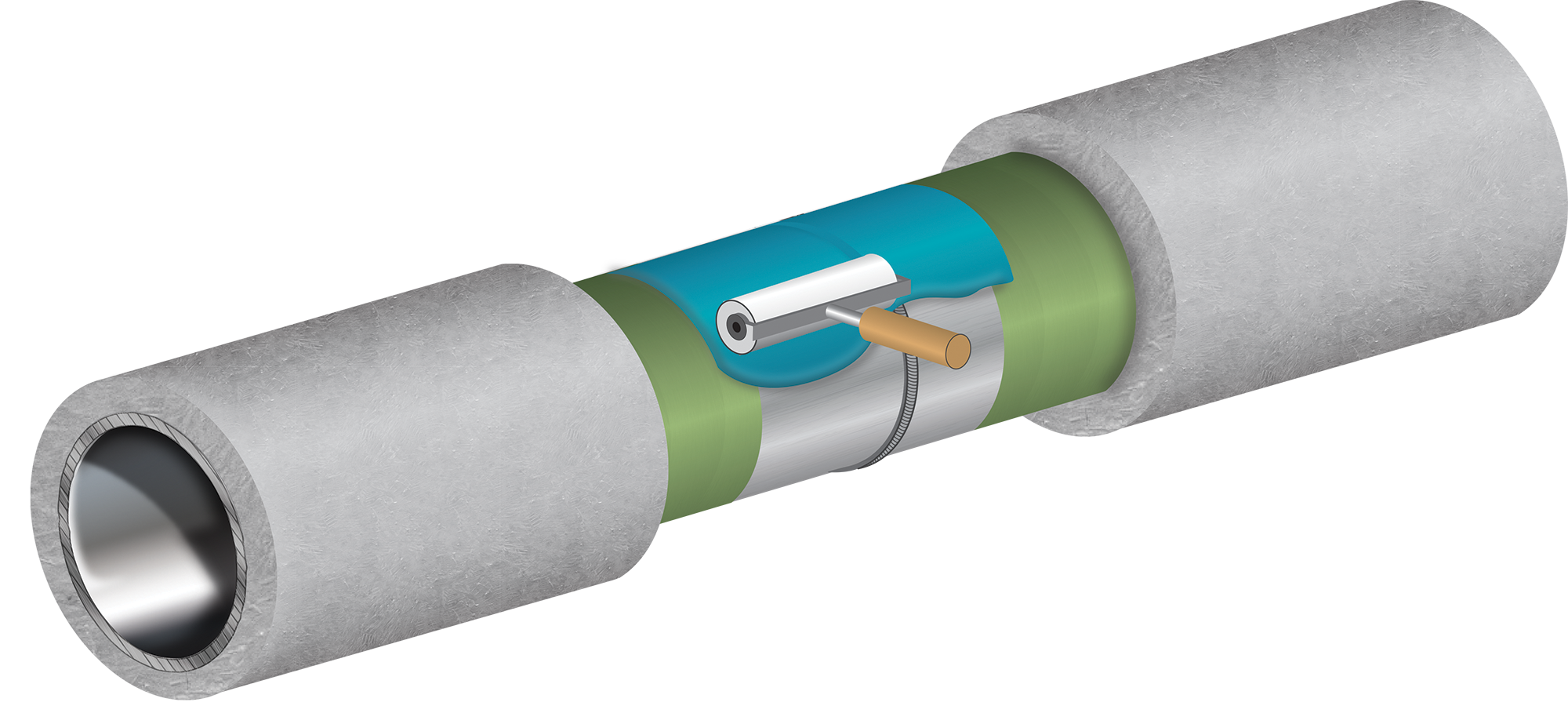

It is a two-component epoxy coating system specifically formulated to withstand immediate forcecuring at high build thicknesses, and achieve superior mechanical performance and corrosion resistance. The HBE-OS coating design allows for the fastest offshore cycle-times and protects operating pipelines up to 120°C (248°F). This environmentally friendly, 100% solids, novolac epoxy system can either be spray applied or brush applied to the intended bare steel substrate.

A single pass application direct-to-metal will achieve a high build coating thickness of 20-40 mils (500-1000 microns).

Reduced Installation Temperatures

HBE-OS requires significantly lower application temperatures (110°C) vs FBE (250°C) resulting in reduced installation times.

State-of-the-Art Formulation

The high build coating is designed to be force cured at 110°C (230°F) after application to achieve 60-90 second cure times and perfect porosity ratings.

Exceeds FBE Performance Requirements

HBE-OS exceeds FBE performance as specified in USA, British and Canadian test standards.

High Temperature Corrosion Protection

HBE-OS coating system was designed to protect operating pipelines up to 120°C (248°F).

High Build in Single Coat

A single pass application direct-to-metal will achieve a high build coating thickness of 20-40 mils (500-1000 microns).

Offshore Uses

Mainline pipelines, rehabilitation projects, girth weld field joints, damage and holiday repair to FBE, pipeline valves, fittings and bends.

Applications

Documentation