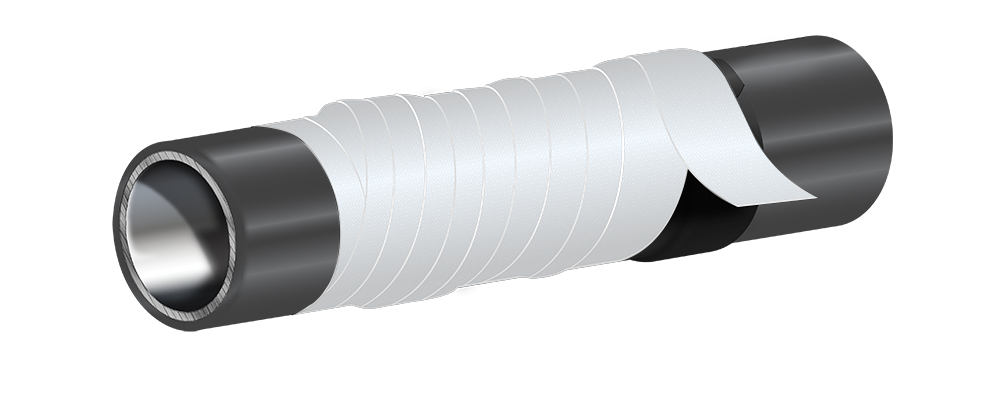

Impact Protection for Pipeline Coatings

WrapidShield PU

Provides high impact resistance and compressive strength.

No performance deterioration when exposed to UV.

Excellent mechanical protection against rocky backfill materials, indentations, soil shear and impacts.

Rapid and reliable installation.

Canusa-CPS’ WrapidShield PU is a composite wrap material consisting of a glass-fibre fabric impregnated with a solvent free moisture curing polyurethane resin, engineered to provide high impact resistance and compressive strength when used as a protective layer over top of anti-corrosion coatings.

The material resists impact damage due to rocky backfill materials or offshore lay barge rollers. WrapidShield PU helps to resist any impact during the construction process.

High Performance System

- Provides excellent additional impact and indentation resistance to coatings.

- Wide temperature range during application and in service.

- Good performance in cold, hot and wet environments.

- Good performance in chemically aggressive environments, such as Acetone, MEK, Toluene, Gasoline, Ethyl alcohol and many others.

- Good resistance to ageing, within operational temperatures.

Rapid and Reliable Installation

- Fast and easy field application, no complex equipment required.

- Can be applied in atmospheric and submerged conditions.

- Fast and complete curing in ambient conditions.

- Pre-impregnated, no field mixing required.

Applications