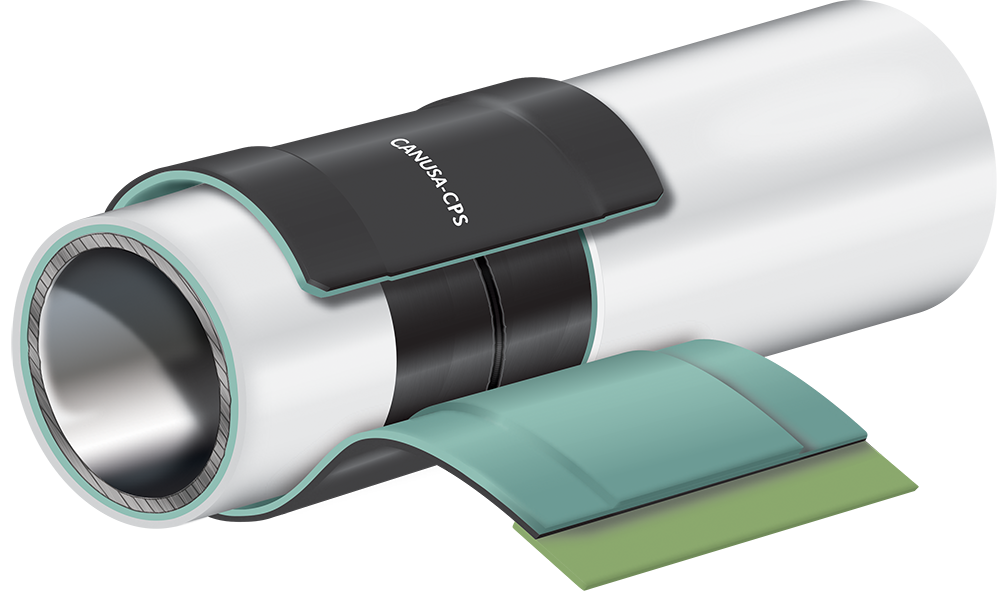

Field-Applied 3LPP System

GTS-PP

Factory Grade™ 3LPP Coating Technology.

Proven compatibility and fusion.

Easy to install with process control.

Engineered for maximum efficiency.

GTS-PP 3LPP field-applied coating system remains the world’s leading joint coating for 3LPP coated pipelines.

Being comprised of the same materials as the 3LPP factory-applied coatings, the GTS-PP system offers equivalent performance as the factory-applied coating. GTS-PP fuses to the 3LPP factory-applied coating with relatively low installation temperatures. Additionally, the GTS-PP system is fully compatible for use with induction heating and Canusa’s IntelliCOAT®.

Factory Grade™ 3LPP Coating Technology

- Polypropylene (PP) top coat delivers mechanical protection and resistance to moisture absorption critical for high temperature anddeepwater pipelines.

- High temperature liquid epoxy or fusion bonded on steel provides Factory Grade™ resistance to cathodic disbondment and allows forlow installation temperatures.

- PP copolymer layer bonds the PP top coat to the epoxy and fuses to the factory-applied coating to eliminate the possibility of moisture ingress.

Proven Compatibility and Fusion

- Proven to provide consistent fusion to the factory-applied 3LPP coating with efficient installation.

Easy to Install with Process Control

- Factory Grade™ performance achieved with low installation temperatures using uniform induction pre-heating technology.

- Can be installed directly by contractors, supported by Canusa-CPS’ industry leading field service team.

- Can be combined with the patented IntelliCOAT® systems, providing a fully automated, efficient and safe installation.

Engineered for Maximum Efficiency

- Patented Reduced Edge Thickness design enhances installation efficiency and allows for elevated thickness applications.

- Automated tube welding eliminates overlap/closure system typical of traditional sleeve systems, allowing for uniform thickness and cycle time reduction.