High Build Epoxy Coating for High Temperature Operating Pipelines

HBE-HT

State-of-the-art epoxy coating system.

Variety of uses.

Exceptional performance.

Great mechanical properties.

The Canusa HBE-HT is a state-of-the-art two component epoxy coating system which has been specifically formulated for high temperature pipelines.

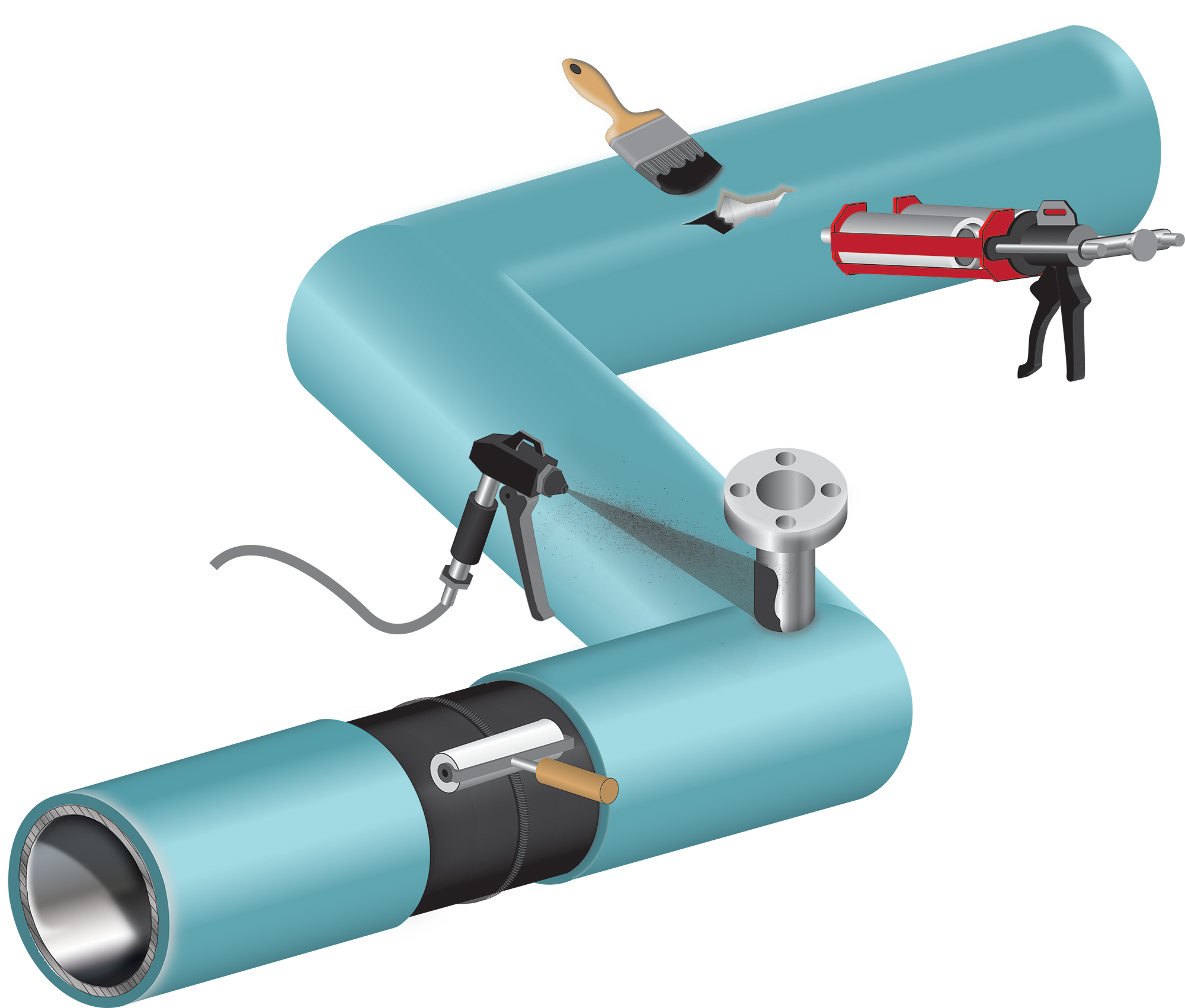

Applied to bare steel, HBE-HT has proven to withstand operating temperatures up to 150°C (302°F) with exceptional performance. HBE-HT is used for protection of pipeline field joint girth welds, valves and fittings, as a holiday repair material on FBE coated pipe or for pipeline coating rehabilitation projects. This superior, 100% solids, novolac epoxy system can either be spray applied or brush applied to the intended substrate.

High Temperature Corrosion Protection

- HBE-HT coating system is designed to protect pipelines operating up to 150°C.

- The unrivaled performance of HBE-HT also includes, but is not limited to, protecting offshore pipelines operating at 120° C.

Exceeds FBE Performance Requirements

HBE-HT exceeds FBE coating performance requirements, including impact resistance, hot water soak adhesion and resistance to cathodic disbonding, as specified in USA (NACE RP0394), British (CW6), and Canadian (CSA Z245.20) test standards.

State-of-the-Art Formulation

Epoxy Phenol Novolac technology combined with proprietary amine cure chemistry allows the HBE-HT coating to maintain adhesion stability after extended aging in hot water and hot dry air.

High Build in Single Coat

A single pass application direct-to-metal will achieve a high build coating thickness of 20-40 mils (500-1000 microns).

Variety of Uses

- Mainline pipelines, rehabilitation projects, girth weld field joints, damage and holiday repair to FBE coated pipe, or pipeline valves, fittings and bends.

- HBE-HT can be used on direct to steel applications as a mainline coating. The product has great mechanical properties and can be used in open-cut road crossings.