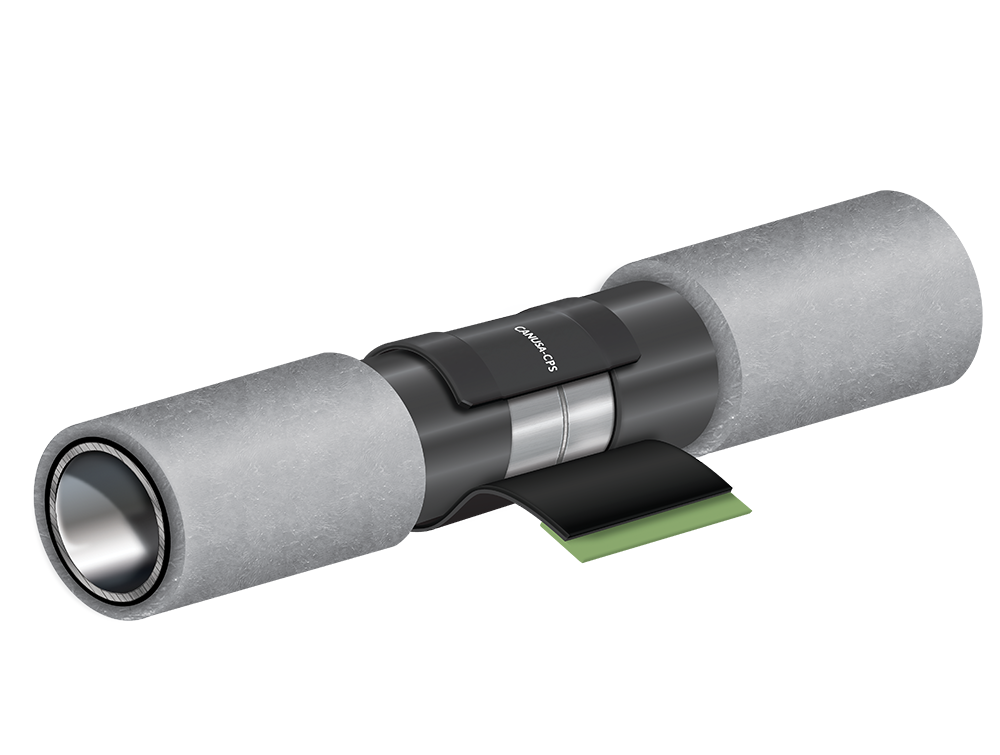

Wraparound Sleeves for Offshore Pipeline Joints

MIS-65

Superior direct-to-pipe corrosion protection.

Endures harsh infill operations.

Robust and reliable.

Maximizes cost savings.

MIS-65 heat shrinkable sleeve series provides superior direct-to-pipe corrosion protection for offshore pipeline joints.

The product has been specifically developed to meet the demanding offshore installation times while providing consistent joint-to-joint performance and easily enduring harsh infill operations.

Robust and Reliable

- Crosslinked polyethylene backing works with purpose engineered adhesive to provide tight seal against corrosion at the pipe surface.

- Adhesive is compatible with a variety of mainline coatings including 3LPE, 3LPP, FBE, DFBE, CTE and AE.

Infill Ready

- MIS-65 shrink sleeves are designed to be used with lay barge applied infill systems including PU foam and solid PU and withstand high temperatures associated with the infill processes.

- The MIS-65 sleeve system provides long term corrosion protection for pipelines operating up to 65°C.

Maximize Cost Savings

- One-piece sleeve construction with pre-attached closure reduces installation time, resulting in high production rates.

- Low preheat adhesives result in fast pipe preparation and reliable sleeve application.

Applications

Offshore Pipelines

Oil & Gas

Infill Systems

Reel, J & S Lay

Girth-Weld Joints