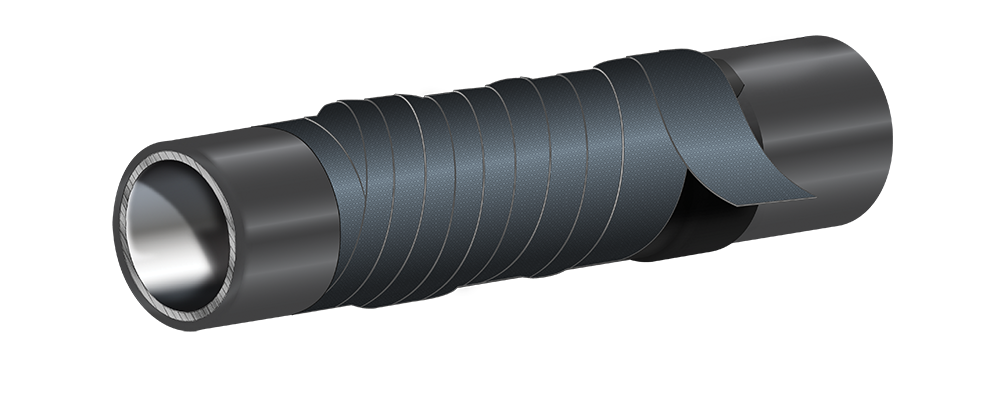

Fiber-Reinforced Composite Mechanical Protection System

ScarGuard

Minimizes the need for costly repairs after pull back.

Provides robust protection of the underlying

pipeline coating.

Protection against impact, abrasion, gouge, punctures and tears that may result from directional drilling.

Cure options for any environment.

ScarGuard provides superior mechanical protection to field joint coatings on directionally drilled pipelines or areas where severe backfill conditions are present.

Moisture curable polyurethane impregnated fibreglass protection system for joint coating, the ScarGuard provides effective protection against abrasion and wear forces that occur during the pull-through or backfilling operations.

Bury, Bore or Drill with Confidence

Provides unparalleled protection against impact, abrasion, gouge, punctures and tears that may result from directional drilling, rough handling, native backfills or severe in-service conditions.

Cure Options for any Environment

Fast cure, slow cure, UV-Curable, UV-Resistant – all available options to suit a wide range of project cycle time requirements and construction conditions.

Non-Shielding

Suggested voltages for high-spark voltage testing as per NACE SP0188 pass through ScarGuard to ensure the anticorrosion coating can be tested for integrity after pull-through and protected for the lifetime of the asset.

Fast, Easy Installation

ScarGuard products are simply wrapped onto the existing coatings surface and activated by water. Pre-impregnated moisture cured polyurethane resin means – no field mixing or saturation required!