Visco-Elastic Adhesive Based System

WrapidBond®

Fast field-friendly installation.

Suitable for a wide range of diverse applications.

A trusted platform since 2011.

Non-toxic and environmentally friendly.

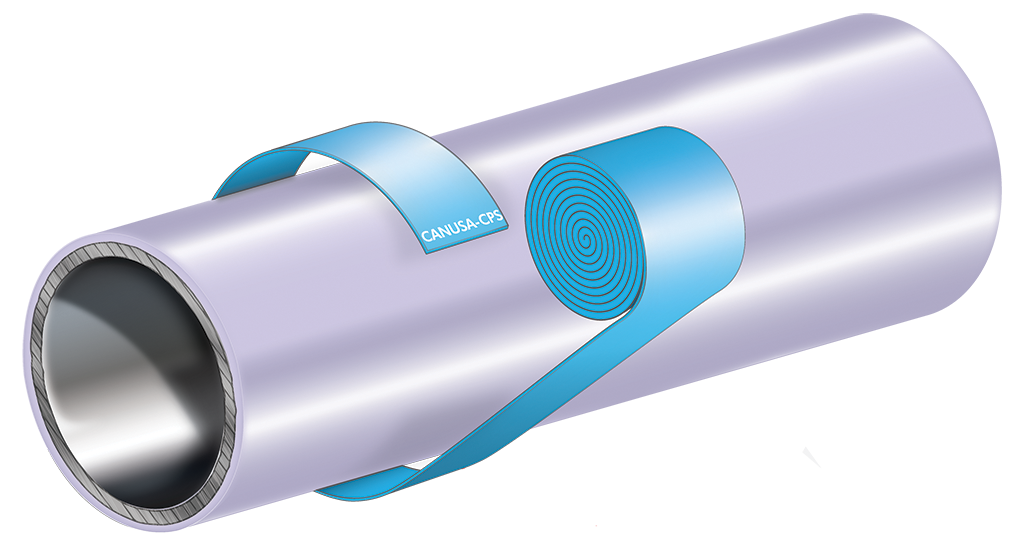

WrapidBond® is a visco-elastic adhesive based system for pipeline corrosion protection.

A wraparound corrosion protective coating consisting of a modified and reinforced visco-elastic adhesive applied onto a polyethylene carrier film. Supplied in roll form, WrapidBond® provides superior corrosion protection by providing a barrier to water and oxygen. WrapidBond® is for use on underground pipelines, and steel structures.

Adhesion & Creep Resistance

- Specially formulated adhesive bonds to even the most difficult substrates and provides good elevated temperature creep resistance and resistance to soil stresses.

- Improved soil stress resistance is achieved with the installation of WrapidCoat® PVC or PE outer wrap.

Wide Range of Applications

WrapidBond® FST is ideally suited for a diverse range of pipeline applications for coating repair or use on new pipeline construction including; transition areas on below ground pipelines, special sections such as bends, tees, flanges, tanks chimes, etc.

Full System Approach

The WrapidBond® product line utilizes the combination of WrapidBond®, WrapidBond® FST and WrapidCoat® to cover numerous unique applications, under varying conditions to allow for fast and easy installation with minimal access, working footprint, within cold or hot environments, and even on operating pipelines without the need for shut down.

Field Friendly

- Long shelf-life, with various widths available with convenient roll lengths for ease of inventory.

- Fast installation with instant adhesion to steel and other base surfaces without applying primer.

- No drying or hardening time.

- Plastic-elastic properties allow self healing ability if damaged.

Applications